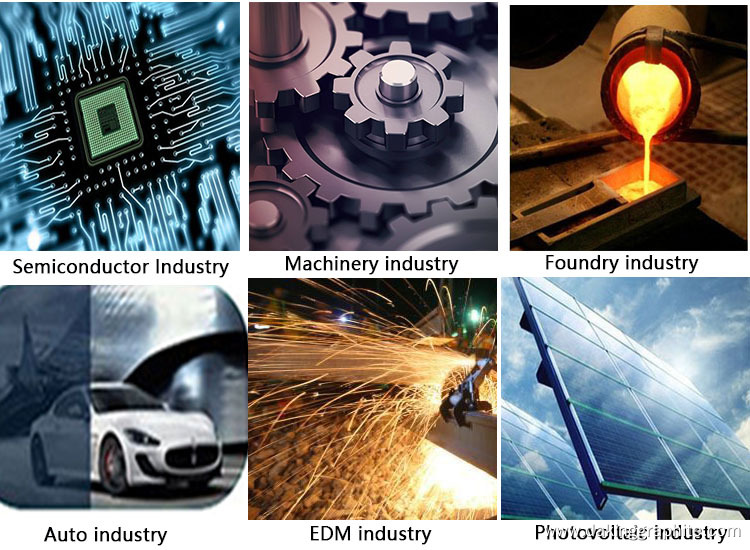

Carbon graphite molds are widely used in various industries as a result of their unique features such as exceptional strength, durability, thermal resistance, and electrical conductivity. Anti-oxidation carbon graphite molds are produced with advanced technology, ensuring that the materials used are of the highest quality. The molds are carefully crafted to ensure that they offer top-notch performance, which increases the overall efficiency of the manufacturing process.

Carbon graphite molds are widely used in various industries as a result of their unique features such as exceptional strength, durability, thermal resistance, and electrical conductivity. Anti-oxidation carbon graphite molds are produced with advanced technology, ensuring that the materials used are of the highest quality. The molds are carefully crafted to ensure that they offer top-notch performance, which increases the overall efficiency of the manufacturing process.

One of the significant benefits of using anti-oxidation carbon graphite molds is the cost savings it affords manufacturers. It offers improved longevity, and as such, requires less frequent replacement, reducing the overall cost of production. In addition, the molds require minimal maintenance, which translates to further cost savings.

Another advantage is the high dimensional stability and accuracy offered by anti-oxidation carbon graphite molds. This ensures that products manufactured using the molds are consistent in quality. This is highly desirable, particularly in industrial sectors such as the automotive and aerospace industries, where precision manufacturing is paramount.

In conclusion, anti-oxidation carbon graphite molds offer numerous advantages to manufacturers. They are an ideal solution for high-temperature applications and offer superior durability and reliability. The cost savings, dimensional stability, and accuracy make them an invaluable asset across various industries. Therefore, it's crucial for manufacturers to consider anti-oxidation carbon graphite molds for their manufacturing processes.

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.