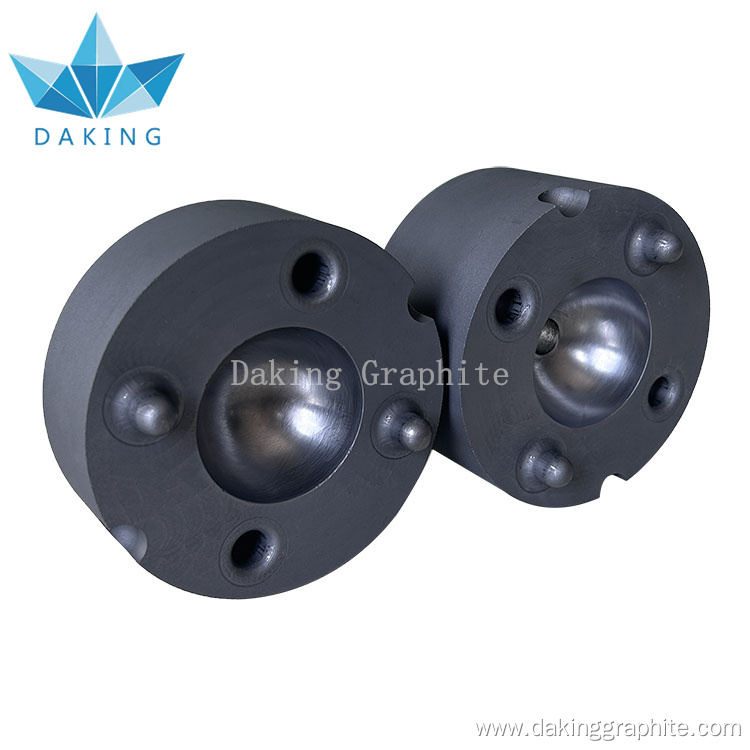

Graphite mold is a versatile material that offers several advantages over other casting materials due to its excellent thermal conductivity, corrosion resistance, durability and processability. Its unique properties make it ideal for metal casting, especially high melting point metals and corrosive alloys where high precision and accuracy are required.

What are the advantages of graphite molds compared to molds made of other materials?

Graphite molds are one of the most commonly used materials in metal casting and have certain advantages over other materials due to their unique physical properties.

1. Graphite molds have excellent thermal conductivity, which makes them ideal for casting high melting point metals such as aluminum, copper and iron. This is mainly because graphite conducts heat and electricity much better than other materials commonly used in metal casting, such as sand, ceramics or plaster.

2. Graphite molds have excellent corrosion resistance, which makes them the perfect material for casting corrosive metals such as brass or bronze. Unlike sand or ceramic, graphite molds are less likely to react with cast metal, reducing the risk of surface defects and material degradation.

3. Graphite molds are extremely durable and can withstand repeated use without losing their dimensional stability or surface finish. It is resistant to wear and tear and can easily withstand the high pressure and temperature involved in the metal casting process. This means that compared to other mold materials, graphite molds can be used to cast large quantities of metal parts without the need for frequent replacement or repair.

4. Graphite molds are easy to machine and can be customized to meet specific casting requirements. It can be easily engraved or machined using computer-controlled equipment to create complex and intricate designs with high accuracy and precision. This makes graphite molds ideal for casting parts with complex geometries or fine details not possible with other casting materials.

In summary:

Graphite mold is a versatile material that offers several advantages over other casting materials due to its excellent thermal conductivity, corrosion resistance, durability and processability. Its unique properties make it ideal for metal casting, especially high melting point metals and corrosive alloys where high precision and accuracy are required.

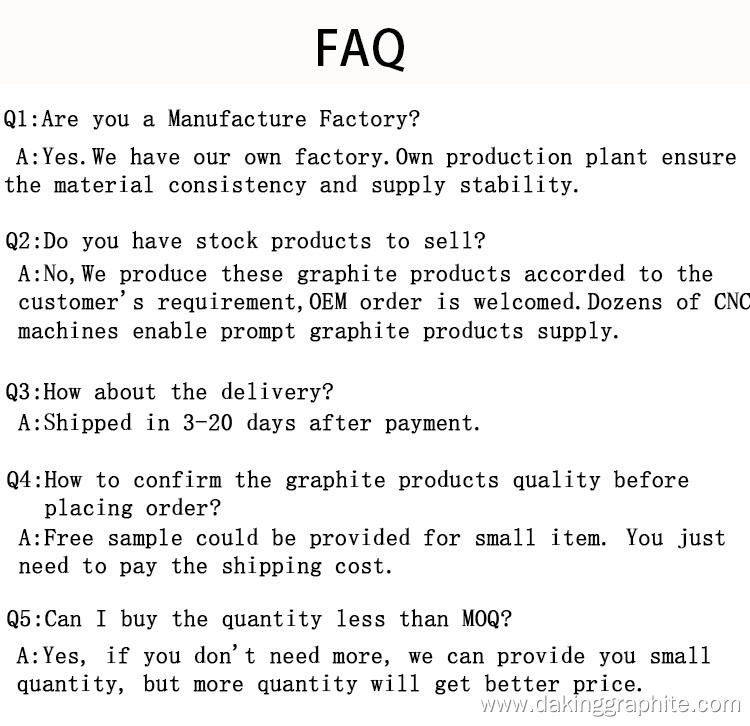

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.