Aaluminum smelting graphite crucible, as a high-performance and highly durable material, has been widely used in metal casting, slag prevention and other industries. As long as you pay attention to details and perform proper cleaning and maintenance during use, you can extend its service life and improve work efficiency and production efficiency.

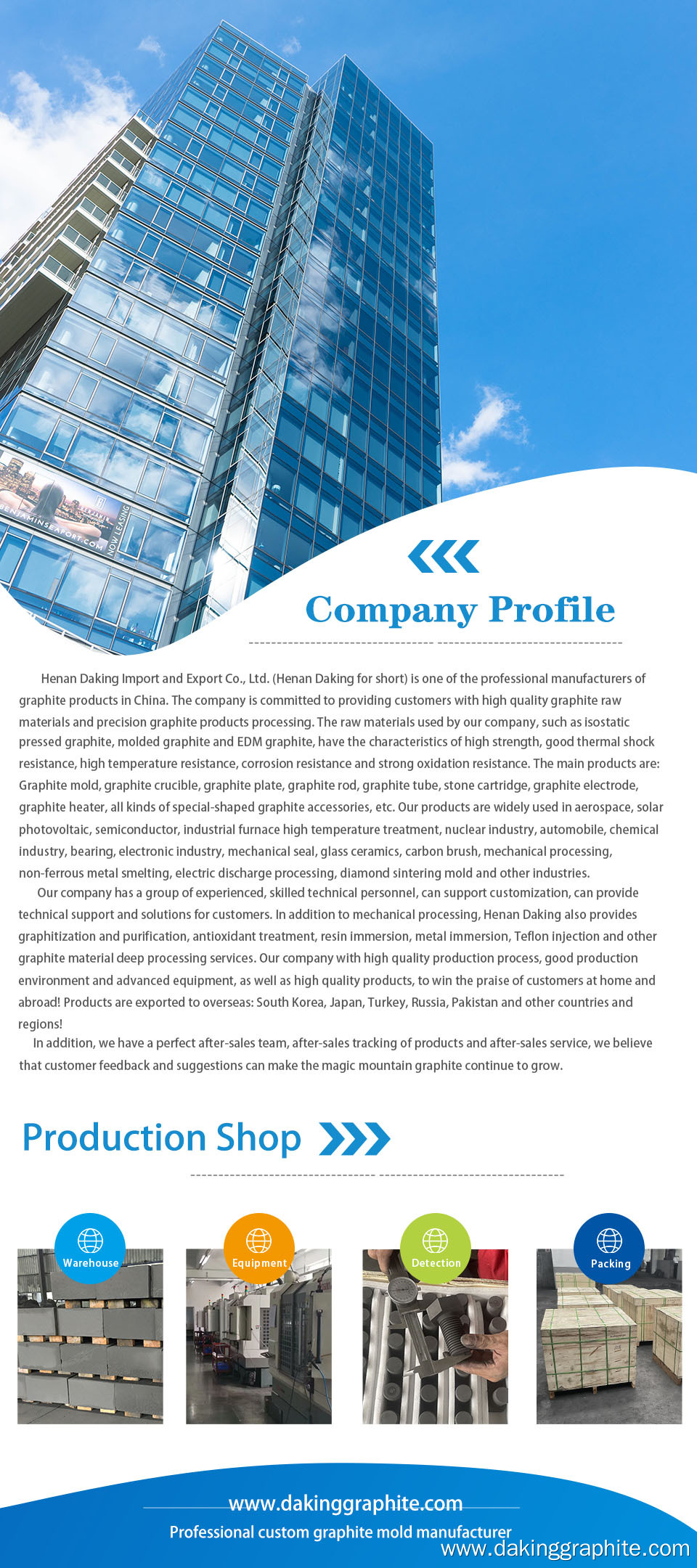

When it comes to aluminum smelting, we have to mention the graphite crucible. The raw material used in this graphite crucible is high-purity graphite, which is processed by CNC. It has excellent properties such as high temperature resistance, chemical stability and mechanical strength, and is often used in high-temperature smelting and heat treatment industries.

Graphite crucible has the following advantages in aluminum smelting:

The molten aluminum graphite crucible has the characteristics of graphite materials such as high stability, small thermal expansion coefficient, large thermal conductivity, and impact resistance. The mechanical strength and corrosion resistance of the quenched graphite crucible are improved, and the bottom of the graphite crucible is reinforced. The thick finish also improves its durability. In addition, the aluminum melting graphite crucible also has a very good feature, that is, it can avoid aluminum reaction or metal precipitation during the melting process and improve its stability.

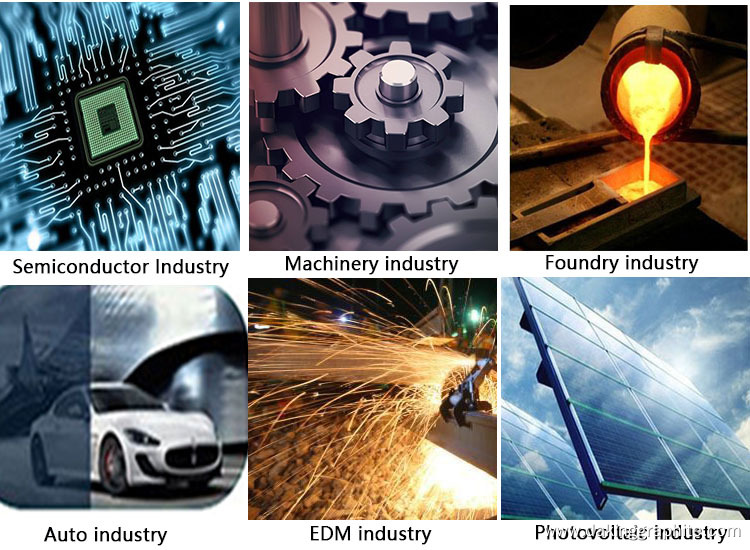

In what fields are graphite crucibles used?

Aluminum melted graphite crucibles are widely used in the fields of aluminum, aluminum alloys, copper, copper alloys, magnesium, magnesium alloys, zinc and other non-ferrous metals, and can also be used in iron-making, chemical and other industries. Commonly used in casting, electrolysis, plasma spraying, plasma heat transfer, crystal growth, high temperature heat treatment, graphitization reaction and other fields.

In general, aluminum graphite crucible, as a high-performance and highly durable material, has been widely used in metal casting, slag prevention and other industries. As long as you pay attention to details and perform proper cleaning and maintenance during use, you can extend its service life and improve work efficiency and production efficiency.

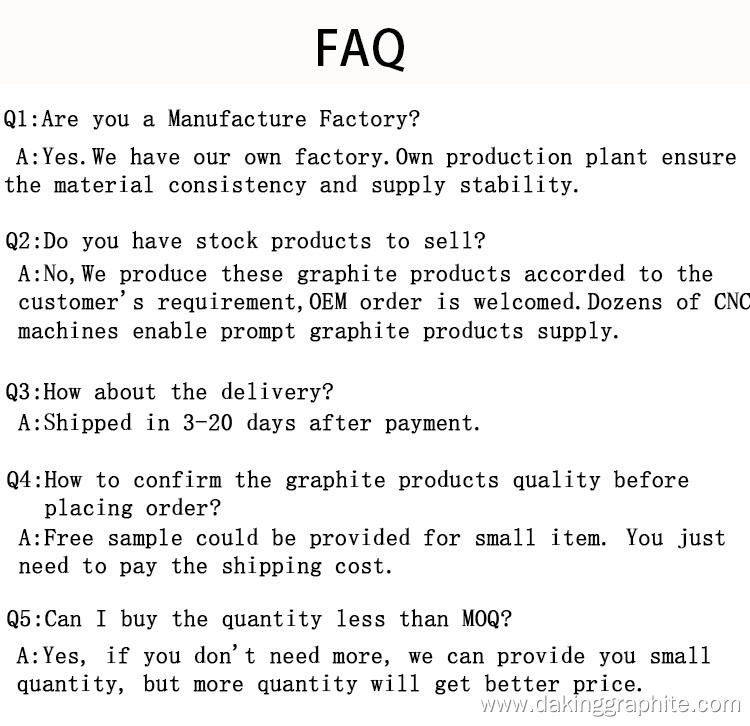

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.