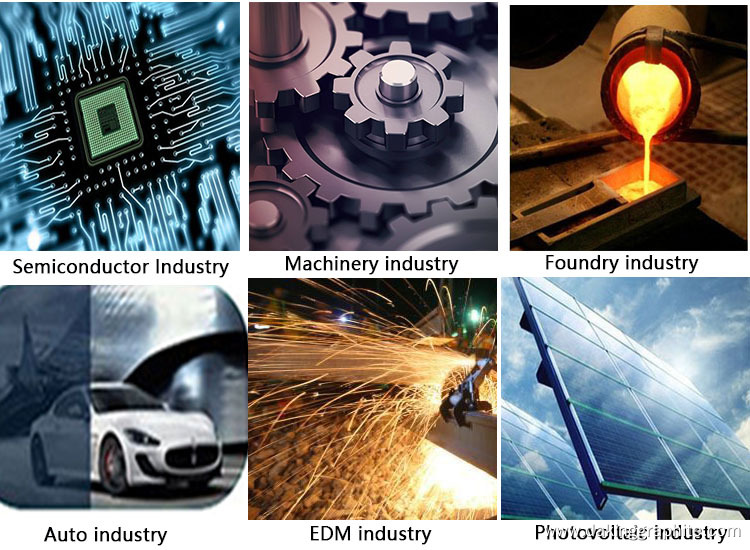

Graphite accessories for vacuum furnaces are widely used in many fields, especially in high-temperature furnaces, vacuum furnaces and other equipment.graphite accessories for vacuum furnaces have many excellent properties and wide applications, and can meet various complex and demanding usage scenarios.

Graphite accessories for vacuum furnaces are widely used in many fields, especially in high-temperature furnaces, vacuum furnaces and other equipment. Here are some specific applications:

Heating element: In the vacuum furnace, the graphite heating element is one of the core components. Because graphite has excellent electrical conductivity and chemical stability, it can maintain stable performance in high temperature and high vacuum environments. In addition, graphite heating elements also have the characteristics of high efficiency, corrosion resistance, and long life.

Heat shield: In vacuum furnaces, graphite heat shields are used to reduce heat loss in the furnace cavity and improve heating efficiency.

Heat sink: The function of the graphite heat sink is to absorb the heat in the furnace body and ensure the uniform temperature distribution of the furnace body.

Crucible: In a vacuum furnace, a graphite crucible is used to hold and protect the heated workpiece.

Conductive materials: used in the electrical industry to make electrodes, brushes, carbon rods, carbon tubes, positive electrodes of mercury current flow devices, etc.

Lubricating materials: often used as lubricants in the machinery industry. Many equipment that transport corrosive media widely use graphite materials to make piston cups, sealing rings and bearings. They do not need to add lubricating oil when running. Graphite emulsion is also a good lubricant for many metal processing (wire drawing, tube drawing).

Good chemical stability: Processed graphite has the characteristics of corrosion resistance, good thermal conductivity, and low permeability. It is widely used in the production of heat exchangers, reaction tanks, condensers, combustion towers, absorption towers, coolers, and heating. filters, pumps and equipment. It is widely used in petrochemical industry, hydrometallurgy, acid and alkali production, synthetic fiber, papermaking and other industrial sectors, and can save a lot of metal materials.

In short, graphite accessories for vacuum furnaces have many excellent properties and wide applications, and can meet various complex and demanding usage scenarios.

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

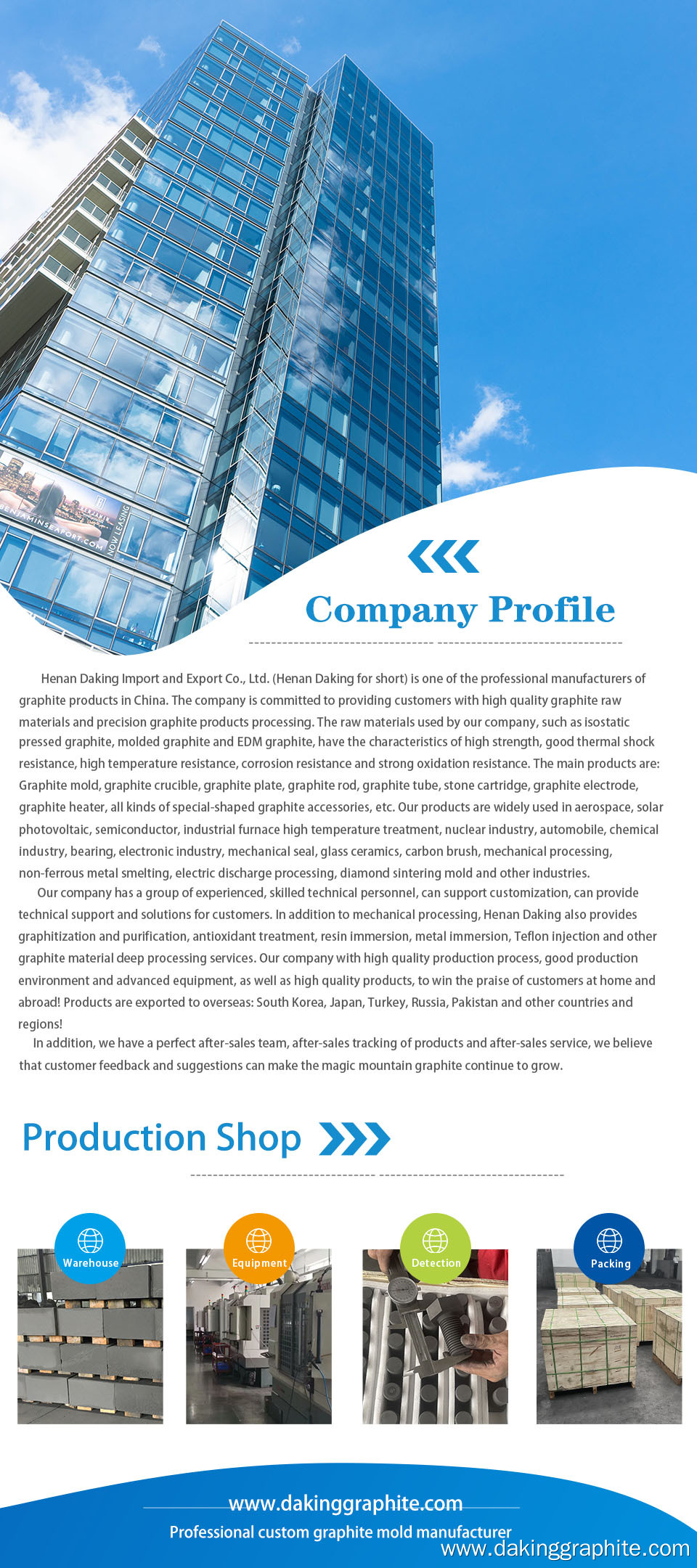

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.