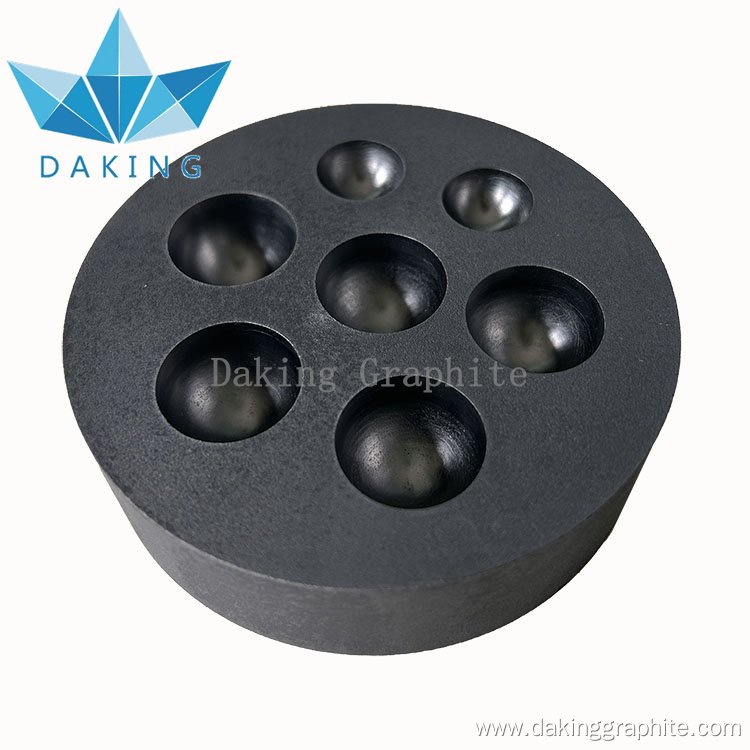

Sintering graphite mold play a vital role in the manufacturing industry to produce high-quality parts that meet the stringent requirements of various industries. Their unique properties allow manufacturers to produce precision parts that are stronger, denser, more heat-resistant, and more wear-resistant than parts produced using other manufacturing methods.

What is a sintering graphite mold? What is it mainly used for?

The so-called sintering graphite mold is made of high-purity graphite material. It has excellent thermal stability and high temperature resistance, and is very suitable for sintering applications. The unique properties of this graphite mold allow it to withstand the extreme temperatures and pressures required during the sintering process without cracking or deforming.

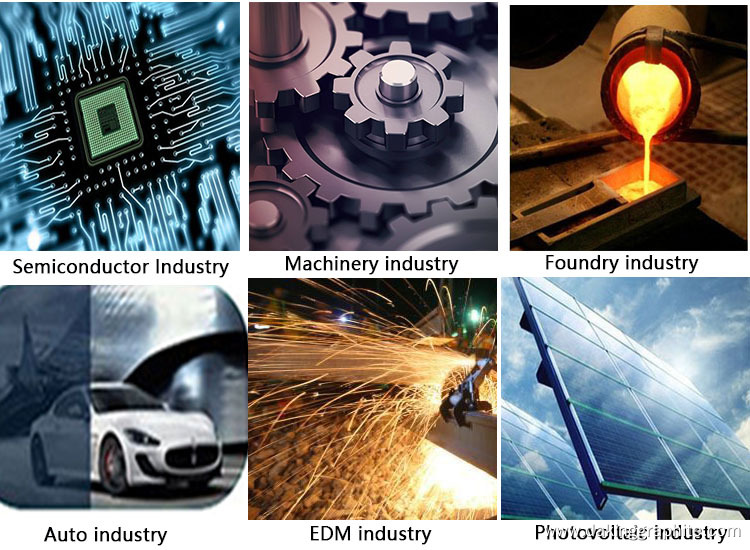

Sintering graphite molds were widely used in the manufacturing industry at that time, such as in the production of ceramics, metals and alloys. The process involves heating powdered materials to a specific temperature so that they fuse together and form a solid mass. The process requires a mold that can withstand high temperatures without melting or deforming, which is where sintering graphite mold come into play.

Of course, sintering graphite molds are not limited to manufacturing. It also includes the production of cutting tools, engine parts, advanced ceramics, and even semiconductor devices. The main advantage of using sintered graphite molds compared to other materials is the ability to produce high-precision, complex shapes with excellent dimensional stability and surface finish.

The sintering process offers several advantages that make it ideal for manufacturing applications. For example, it can produce parts that are stronger, denser, more heat-resistant, and more wear-resistant than parts produced using other manufacturing methods. Additionally, it is capable of creating complex shapes and intricate internal structures that are often not possible with other methods.

Using sintering graphite mold can produce high-quality products that meet the stringent requirements of various industries. It ensures manufacturers can produce precision parts that meet customer needs while maintaining high levels of efficiency and productivity.

In summary, sintering graphite mold play a vital role in the manufacturing industry to produce high-quality parts that meet the stringent requirements of various industries. Their unique properties allow manufacturers to produce precision parts that are stronger, denser, more heat-resistant, and more wear-resistant than parts produced using other manufacturing methods. Capable of producing highly complex shapes and intricate internal structures, sintering graphite mold is a valuable tool for manufacturers looking to maintain high levels of efficiency and productivity.

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.