Carbon graphite molds for ingot casting offer several advantages in ingot casting, including high thermal conductivity, high temperature resistance, oxidation resistance, thermal shock resistance and cost-effectiveness. Due to these unique properties, they have become popular and widely used in the metallurgical industry.

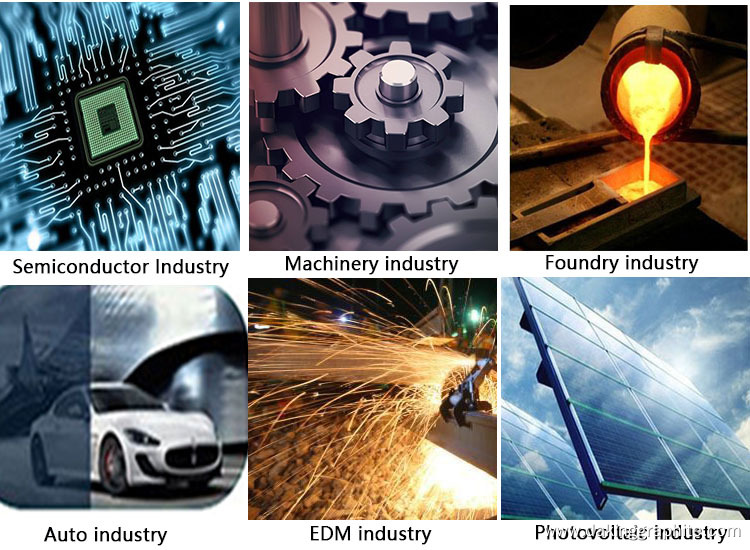

Carbon graphite molds for ingot casting are essential tools in the foundry industry and play an important role in casting gold, silver, copper, and aluminum ingots. Ingot casting has always been an important process for producing various metal alloys to support manufacturing industries. Carbon graphite molds are popular in this field because of their unique properties. In this article, we will discuss the advantages of carbon graphite molds in ingot casting.

1. High thermal conductivity

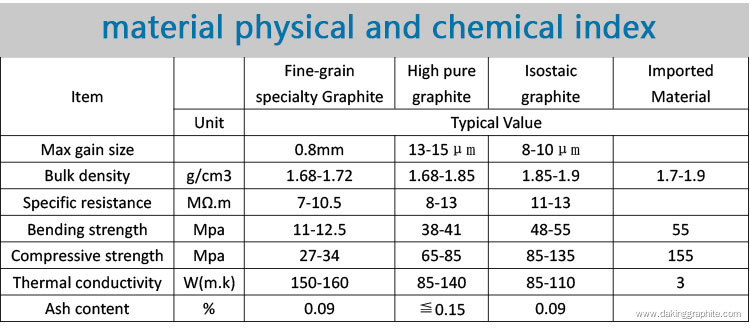

Carbon graphite molds are known for their high thermal conductivity. Due to their excellent thermal conductivity, they can quickly dissipate the heat generated by molten metal. This ensures even and consistent cooling of the metal during solidification. As a result, the ingots produced are of better quality and have fewer defects.

2. High temperature resistance

Carbon graphite molds can withstand high temperatures of 2000 to 3000 degrees Celsius. They can withstand the extreme heat generated during the casting process and retain their shape and form. This ensures that the graphite molds remain durable even after multiple casting cycles, reducing the need for frequent mold replacements.

3. Antioxidant properties

Carbon graphite molds have excellent anti-oxidation properties, which can prevent the mold from oxidizing during the casting process. As a result, the graphite mold remains in good condition and can be used for multiple casting cycles. In addition, the oxidation resistance of graphite molds prevents the formation of oxide impurities, resulting in ingots with fewer impurities and better quality.

4. Thermal shock resistance

Carbon graphite molds can withstand thermal shock during casting due to their excellent thermal properties. Even under rapid temperature changes, the graphite mold maintains its shape and shape, ensuring that the ingot is of good quality without any defects.

5. High cost performance

Casting ingots using carbon graphite molds is cost effective. This graphite mold lasts longer than other molds, reducing the need for frequent mold replacements, which is a cost-saving measure for manufacturers. In addition, the mold's oxidation resistance and excellent thermal conductivity ensure better quality ingots produced and reduce production costs.

in conclusion

Carbon graphite molds for ingot casting offer several advantages in ingot casting, including high thermal conductivity, high temperature resistance, oxidation resistance, thermal shock resistance and cost-effectiveness. Due to these unique properties, they have become popular and widely used in the metallurgical industry. Choosing carbon graphite molds for ingot casting will ensure higher quality ingots and cost savings for the manufacturing industry.

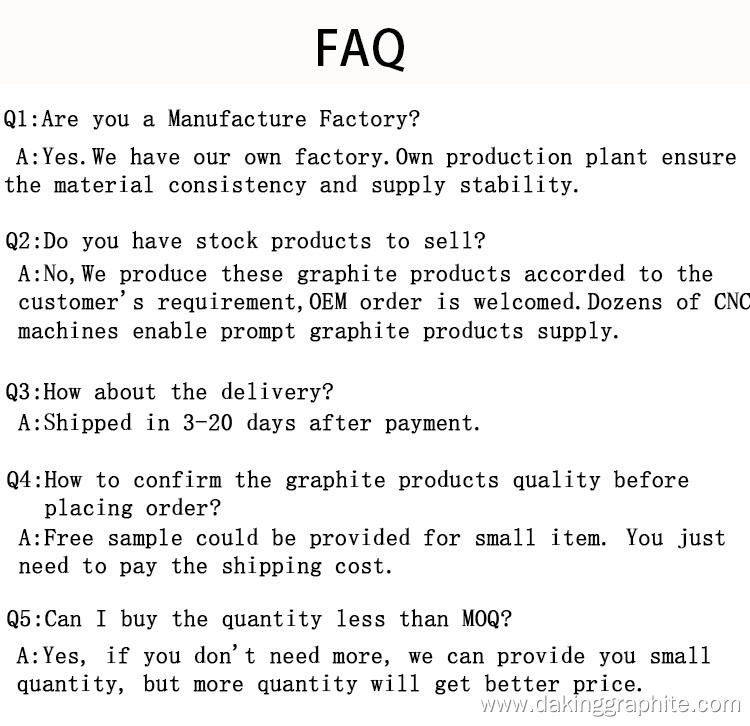

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.