The graphite mold for metal ingot is an essential tool in the metal casting industry. They are durable, produce high-quality ingots, and can be used to cast a variety of metals. The use of graphite molds reduces waste and is environmentally friendly. Although manufacturing is expensive, the benefits of using graphite molds far outweigh its initial cost.

What is a graphite mold for metal ingot?

Graphite mold for metal ingot is widely used in the metal casting industry, especially for casting high melting point metals. Graphite has high thermal conductivity, chemical resistance and low thermal expansion coefficient, making it an ideal material for making molds. Graphite molds are essential tools for producing high-quality, consistent metal ingots.

The steps to use the graphite mold for metal ingot are as follows:

The process of using graphite molds begins with preparing the mold. This includes cleaning the graphite mold surface, applying release agent, and placing the mold in a furnace to preheat. Once the mold is preheated to the desired temperature, molten metal is poured into it through a heating pack. The mold is then cooled to allow the metal to solidify, and the ingot is removed.

Graphite mold for metal ingot are used in the foundry industry mainly because of their following advantages:

One of the main advantages of using graphite molds is their ability to withstand high temperatures and pressure. The mold is reusable and its durability ensures consistent quality ingots. The use of graphite molds also reduces the environmental impact of metal casting because graphite molds produce less waste than other forms of moulds.

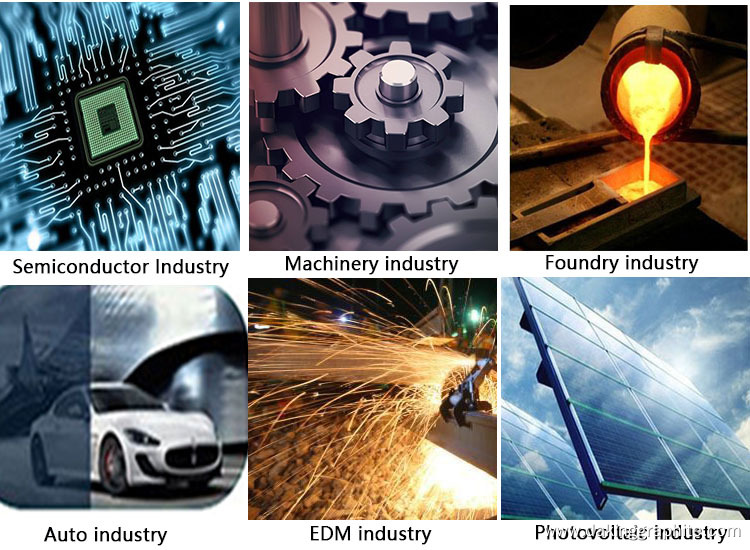

Graphite molds are versatile and can be used to cast a variety of metals, including aluminum, copper, zinc and titanium. Molds can be customized to meet specific requirements such as size, shape and thickness. This makes them ideal for producing metal components used in various industries including aerospace, automotive and construction.

One of the challenges with using graphite molds is the cost of manufacturing. Graphite is an expensive material, and the process of making graphite molds requires advanced technology and equipment. However, the cost is offset by the durability of the mold and the high quality of the ingots produced.

To sum up, the graphite mold for metal ingot is an essential tool in the metal casting industry. They are durable, produce high-quality ingots, and can be used to cast a variety of metals. The use of graphite molds reduces waste and is environmentally friendly. Although manufacturing is expensive, the benefits of using graphite molds far outweigh its initial cost.

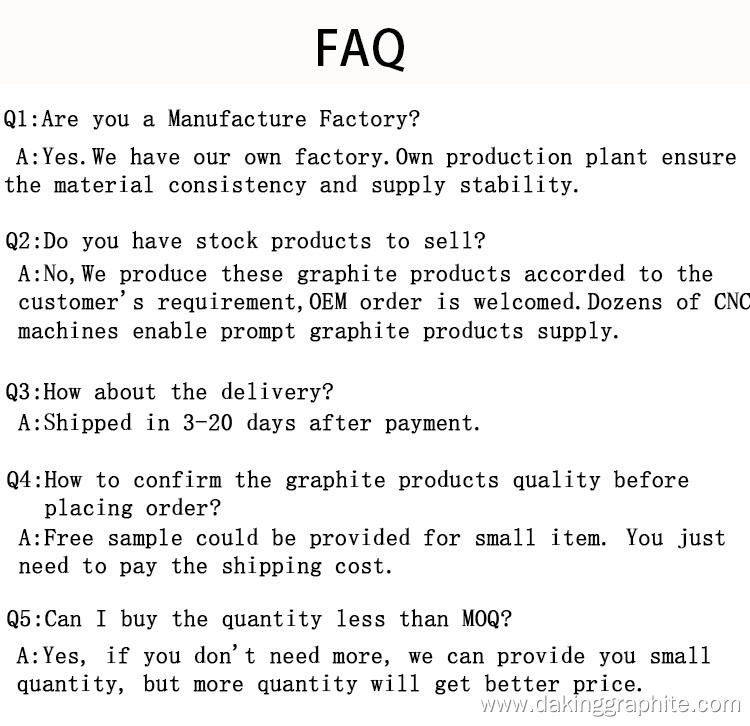

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.