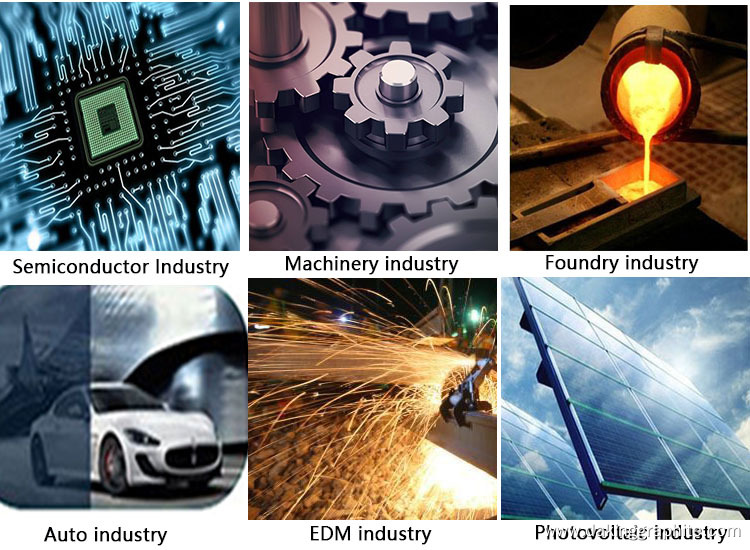

Antimony carbon graphite seal ring have become seals used in major machinery due to their unique characteristics. Graphite seal ring are known to operate at high temperatures and pressures for long periods of time and are therefore often used as a sealing solution where high heat resistance is required. Antimony-impregnated graphite seal ring are also a solution to achieve this goal.

Antimony carbon graphite seal ring have become seals used in major machinery due to their unique characteristics. Graphite seal ring are known to operate at high temperatures and pressures for long periods of time and are therefore often used as a sealing solution where high heat resistance is required. Antimony-impregnated graphite seal ring are also a solution to achieve this goal.

Antimony carbon graphite seal ring are used in mechanical seal applications to prevent fluid escape between two closely mating surfaces. The unique design of this graphite seal ensures that fluid is trapped, creating a high-pressure zone that forces fluid to become trapped. This creates a better seal between the two surfaces and prevents leaks.

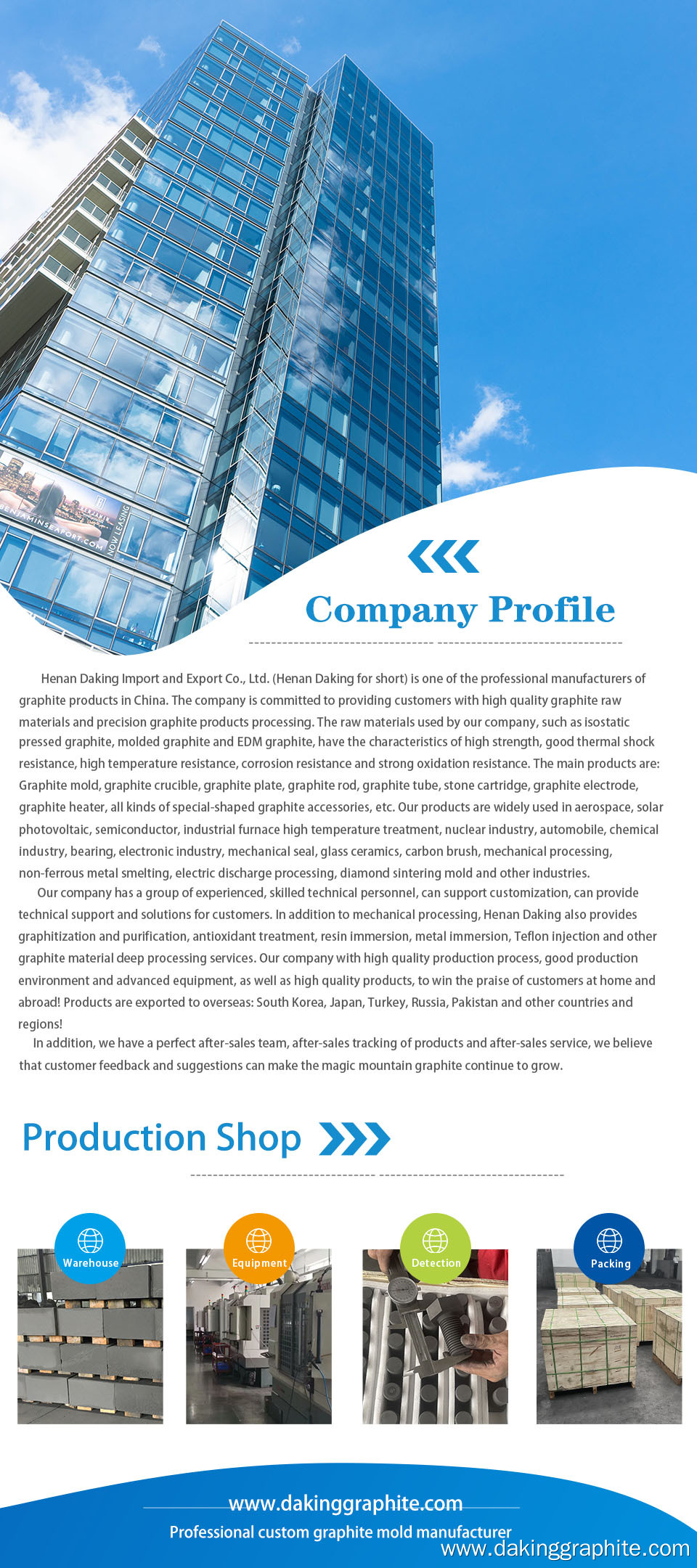

The antimony impregnation process increases the strength of the graphite seal ring and enhances its thermal conductivity. The impregnation process involves soaking graphite seal ring in molten antimony so that the antimony flakes are evenly distributed in the graphite matrix. The resulting material is stronger and has a longer lifespan.

The graphite in the sealing ring is an excellent thermal conductor and can withstand high temperatures. It allows heat to dissipate evenly, reducing the risk of thermal expansion and contraction that can lead to breakage and wear.

Antimony carbon graphite seal ring also exhibit excellent resistance to chemical wear. They are not affected by most chemicals, including acids, alkalis, and solvents, making them the material of choice for use in chemical processing plants. The combination of strength, durability and chemical resistance make these seals ideal for use in harsh industrial environments.

In summary, antimony carbon graphite seal ring offer a range of benefits including high temperature resistance, chemical resistance, durability and strength, making them an ideal sealing solution for a variety of industrial applications. The soaking process causes the graphite to absorb antimony, increasing its thermal conductivity and strengthening the material, making it stronger and more durable. Therefore, antimony carbon graphite seal ring are a cost-effective and convenient sealing solution.

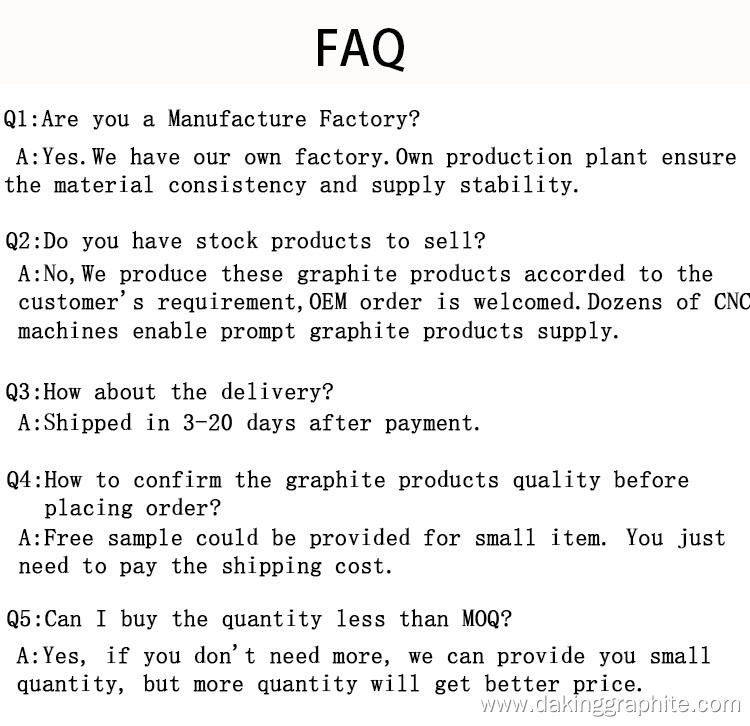

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.