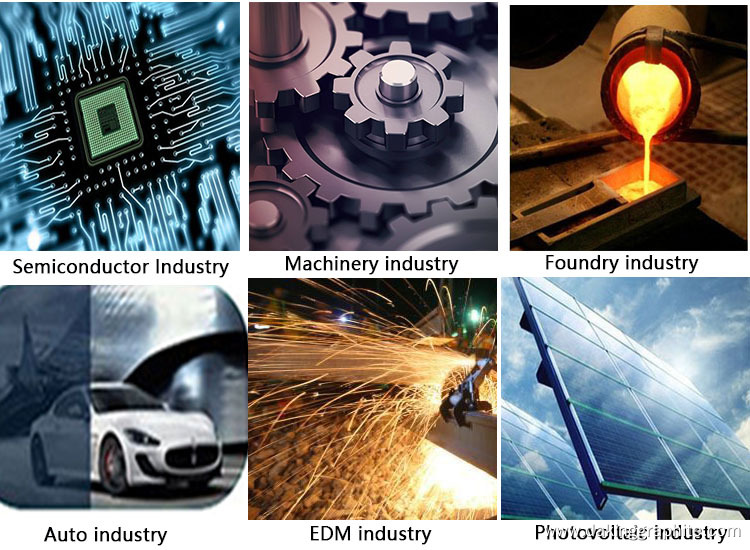

Graphite molds have a wide range of applications. What I want to introduce here is the application of graphite molds in the smelting industry. The smelting industry has very strict requirements for the use of tools, and graphite molds stand out and become an indispensable part of this field.

Graphite molds have a wide range of applications. What I want to introduce here is the application of graphite molds in the smelting industry. The smelting industry has very strict requirements for the use of tools, and graphite molds stand out and become an indispensable part of this field. So how are graphite molds used in the smelting industry? And what impact does the quality of graphite molds have on smelting?

First let’s start with the meaning of smelting, which is the process of extracting metals from ore by heating the ore to high temperatures until it melts. Once melted, the metal can be separated from the impurities in the ore.

Graphite molds are used in melting to shape the molten metal into the desired shape. For example, if you wanted to make a metal sphere, you would pour molten metal into a graphite mold shaped like a sphere. As the metal cools, it solidifies and takes on the shape of the mold. Graphite molds can also be used to cast other shapes such as cylinders, blocks, and plates.

The quality of the graphite mold is critical to the success of smelting as it affects the final shape and quality of the metal product. If the graphite mold is not made of high-quality graphite, it may break during the smelting process. This can cause molten metal to leak from the graphite mold, resulting in product deformation and even damage to the smelting equipment.

In addition to the risk of breakage, lower quality graphite molds may contaminate the molten metal. Graphite molds that are not properly sealed or have cracks or pits on the surface can introduce impurities into the metal. These impurities can affect the strength and durability of the final product.

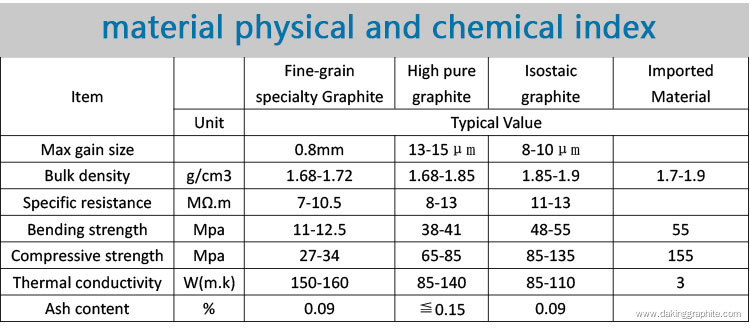

To ensure high-quality graphite molds for smelting, manufacturers use various techniques to create molds that are strong, durable and free of impurities. Graphite molds can be made from natural graphite or synthetic graphite, depending on their intended use. They can also be treated with various coatings or impregnations to further enhance their properties.

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.