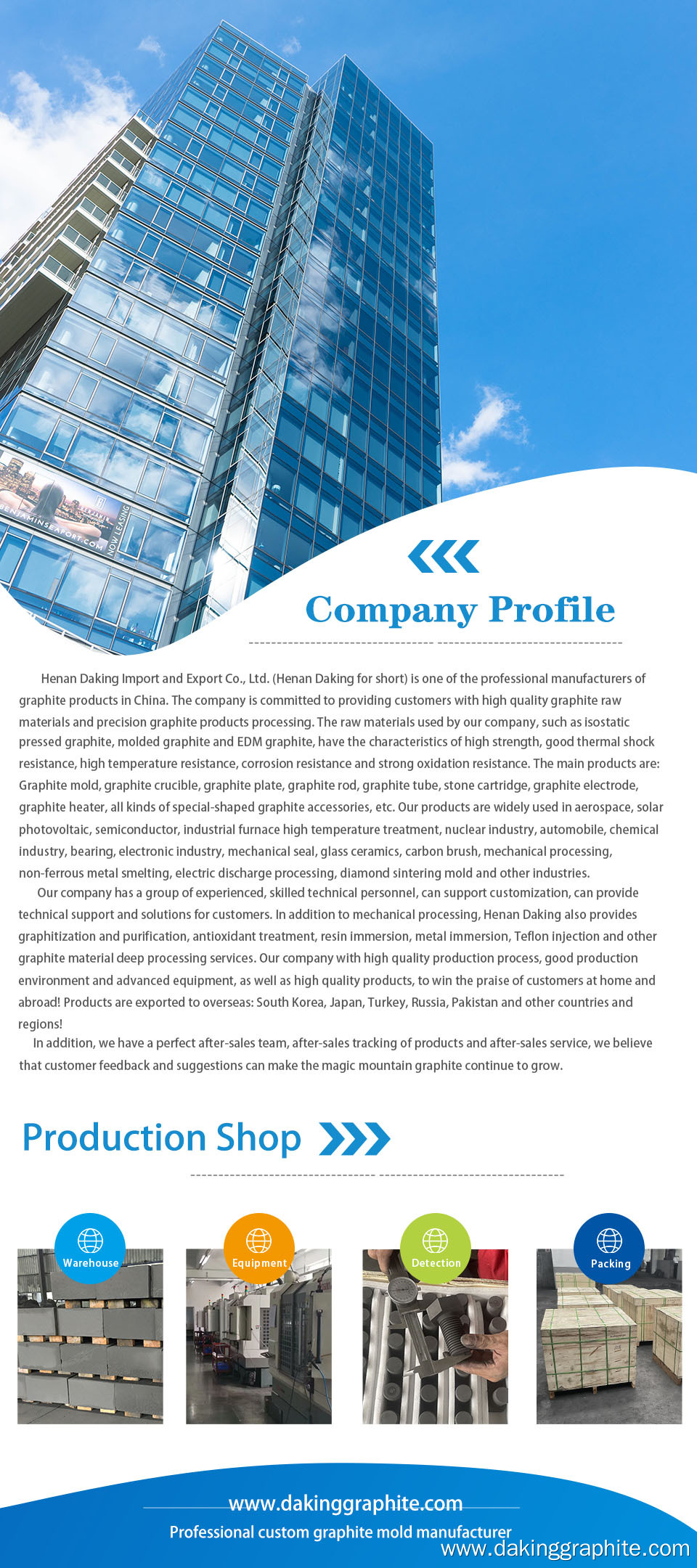

Industrial customized high-density graphite tube is a high-performance graphite product that is common in industries such as electronics, chemistry, petrochemicals, and semiconductors. This graphite tube has become the application material of choice in many industries due to its superior performance.

Industrial customized high-density graphite tube is a high-performance graphite product that is common in industries such as electronics, chemistry, petrochemicals, and semiconductors. This graphite tube has become the application material of choice in many industries due to its superior performance. In this article we tell you about a series of applications of graphite tubes!

Customizing high-density graphite tubes facilitates the specific needs of different industries, and its excellent high temperature resistance and chemical stability make it the most attractive material for industries that need to withstand high temperatures and pressures. Its specific application performance is as follows:

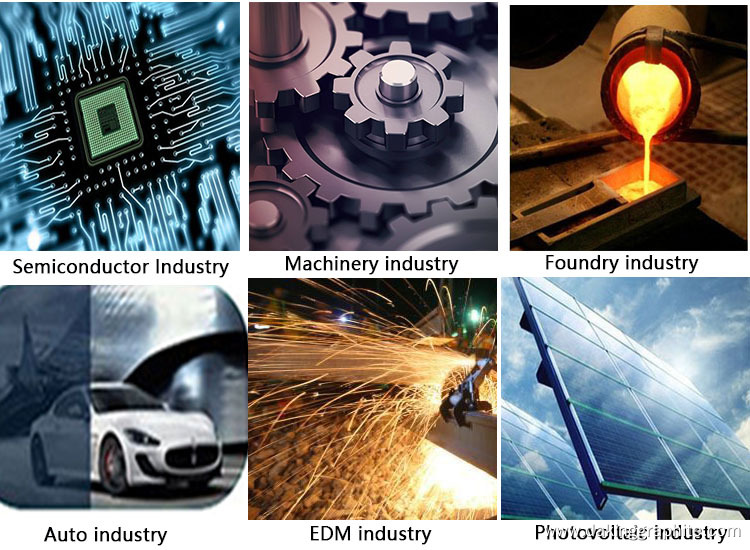

Applications in the chemical industry. High-density graphite tubes can be used in the chemical industry for the transportation, transportation and storage of corrosive chemicals. Secondly it can also be used in heat exchangers, reactors and distillation columns.

Applications in the petrochemical industry. High-density graphite pipes have excellent thermal conductivity, which ensures that the materials being transported maintain a suitable temperature. Therefore, the graphite pipes are very suitable for transporting crude oil and natural gas.

Applications in the semiconductor industry. High-density graphite tubes have low impurity content, which can meet the strict requirements of the semiconductor industry for materials and avoid contamination of electronic components.

Applications in other industries. In addition to the chemical, petrochemical and semiconductor industries, high-density graphite tubes are used in other industries such as aerospace, defense and automotive. Graphite's lightweight properties facilitate its use in industries that require lightweight materials.

Benefits of using custom high-density graphite tubes

Using custom high-density graphite tubes in industry has many advantages, including:

- Corrosion resistance: Graphite pipes are resistant to corrosion by acids, alkalis and other corrosive chemicals.

- High thermal conductivity: Graphite’s high thermal conductivity ensures that transported materials remain at the right temperature.

- Durability: Graphite tubes are durable and their strength and hardness make them ideal for high pressure applications.

- Low impurity content: Customized high-density graphite tubes have low impurity content, making them ideal for use in environments that require high-purity materials.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.