Vibration forming graphite block is a huge progress in graphite block technology, which improves the quality and performance of graphite products.

As a conductor of electricity and heat, graphite has high strength and high thermal stability, and has been widely used in various industrial fields.

Vibration forming graphite block is a huge progress in graphite block technology, which improves the quality and performance of graphite products.

As a conductor of electricity and heat, graphite has high strength and high thermal stability, and has been widely used in various industrial fields.

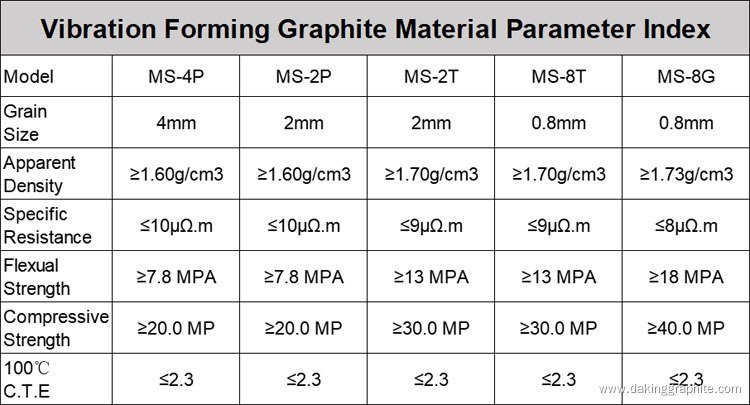

Traditional graphite block molding processes such as extrusion, pressing and injection molding are no longer sufficient to meet the stringent requirements for graphite blocks in the market. The introduction of vibration molding technology has completely changed the production process of graphite blocks. This technology can produce products with improved physical properties. High quality graphite blocks in terms of size, surface quality and density.

The working principle of vibration molding technology is to use vibration to generate uniform pressure on graphite particles placed in the mold. This produces higher quality graphite blocks with a fine surface finish. Additionally, the improved physical dimensions and density of the blocks ensure they have better mechanical strength, thermal shock resistance and electrical conductivity than conventionally manufactured graphite blocks.

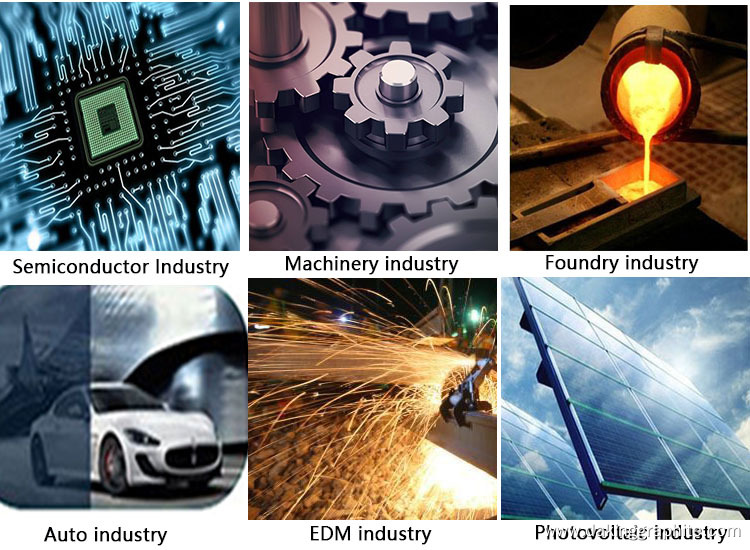

Vibration forming graphite blocks have changed the application of graphite blocks in different industries. Due to its improvement in quality, graphite blocks are used in a wider range of applications, such as glass manufacturing, metallurgical processes, and semiconductor manufacturing.

The emergence of vibration forming graphite blocks solves many defects in the original process. Its benefits are as follows:

1. Reduce production process time. Vibration forming technology is a fast and efficient process that reduces the typical production time of graphite blocks to just a few hours. In addition, the process can produce graphite blocks of different sizes and shapes.

2. Potential for customization. Because the technology allows the production of blocks with varying physical sizes, shapes and densities, engineers and manufacturers can tailor their designs to meet specific application requirements.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.