Graphite crucible, a must-talk tool in high temperature applications. It is an important application component for high-temperature applications, which can meet the use needs in this field and achieve the required results. Graphite crucibles are customizable and range in size from 1kg to 5kg. Of course, graphite crucibles of different shapes and specifications can also be customized according to the application needs of the industry.

Graphite crucible, a must-talk tool in high temperature applications. It is an important application component for high-temperature applications, which can meet the use needs in this field and achieve the required results. Graphite crucibles are customizable and range in size from 1kg to 5kg. Of course, graphite crucibles of different shapes and specifications can also be customized according to the application needs of the industry.

In this article, we will explore the characteristics and uses of graphite crucibles and why they are commonly used in many industries.

Characteristics of graphite crucible:

Graphite crucible is made of graphite material and has strong temperature resistance and corrosion resistance. The following are some basic characteristics of graphite crucible:

1. High melting point: Graphite crucible is known for its high melting point, which ranges from 3,000°C to 3,600°C. This property makes it suitable for high temperature applications such as melting metals, alloys and other materials.

2. Corrosion resistance: The graphite material used to make crucibles has strong resistance to chemicals and corrosion. Therefore, they can withstand contact with molten metal and other corrosive substances during the melting process.

3. Durable and long-lasting: Graphite crucible is strong and durable with long service life. They can withstand multiple heating and cooling cycles without cracking or breaking, making them ideal for repeated use.

4. High thermal conductivity: The high thermal conductivity of graphite crucible can achieve effective heat transfer and ensure a consistent and efficient melting process.

The use of graphite crucible

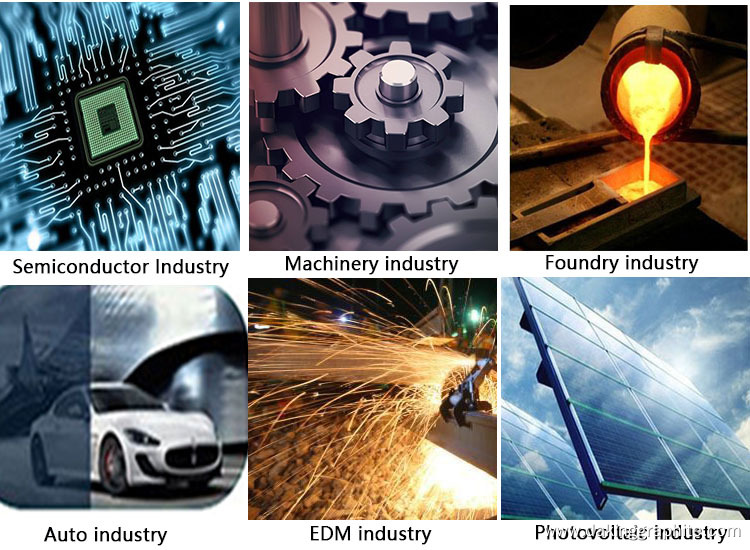

Graphite crucibles are widely used in high temperature applications in various industries, such as:

1. Metal Casting: Graphite crucibles are often used in metal casting processes because they can withstand the high temperatures required to melt metals and alloys.

2. Glass Manufacturing: Graphite crucibles are also used in the glass manufacturing process as they can withstand the high temperatures required during the melting process.

3. Jewelry making: Jewelers use graphite crucibles to melt precious metals such as gold and silver when making jewelry.

4. Chemical processes: Graphite crucibles are also used in chemical processes involving high temperatures and corrosive substances.

Graphite crucibles are available in different sizes, with the most common sizes being 1kg, 3kg and 5kg. Depending on the application, the appropriate crucible size should be selected to ensure safety and efficiency during the melting process.

In summary, graphite crucibles are an important part of high-temperature industrial processes. Graphite's properties, such as its high melting point and corrosion resistance, make it ideal for a variety of applications, including metal casting, glassmaking, jewelry manufacturing and chemical processing. Owing to their different sizes, graphite crucibles are widely used and contribute significantly to the growth and development of the industrial sector.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.