Carbon carbon composite screws are a premium product that offer many advantages over traditional metal screws, including high strength, light weight, corrosion resistance, and high temperature resistance. They are suitable for a wide range of applications including aerospace, defence, automotive, marine and offshore industries.

As a new product on the market, carbon composite screws are popular for their excellent quality and performance such as strength, lightness and durability. It is a screw made of carbon fiber reinforced carbon matrix composite material.

So, what is the carbon-carbon composite screw made of?

Carbon-carbon composite screws are made of carbon fiber reinforced matrix composite material, which consists of carbon fibers bonded together with a matrix made of carbon. The carbon fibers are arranged in a specific direction and direction to ensure maximum strength and stiffness. Carbon-based materials are cured under high temperatures and pressures, resulting in composite materials that are hard, strong and lightweight.

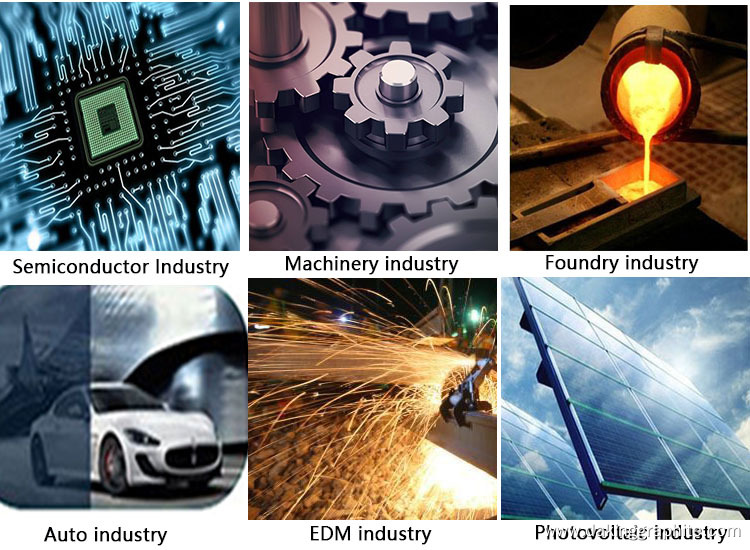

Carbon screws are widely used in many industries due to their unique properties, such as:

1. Carbon Carbon composite screws have a high strength-to-weight ratio, making them a popular choice in the aerospace, defense, and automotive industries.

2. Carbon Carbon screws are much lighter than traditional metal screws, which makes them a popular choice for lightweight structural applications such as aircraft and racing cars.

3. Carbon-carbon composite materials will not degrade or rust over time. This makes it a popular choice in highly corrosive marine and offshore environments.

4. Carbon composite screws can withstand high temperatures without melting or deforming. This makes them ideal for use in high-temperature environments such as rocket engines, gas turbines, and other high-performance engines.

All in all, carbon composite screws are a premium product that offer many advantages over traditional metal screws, including high strength, light weight, corrosion resistance, and high temperature resistance. They are suitable for a wide range of applications including aerospace, defence, automotive, marine and offshore industries.

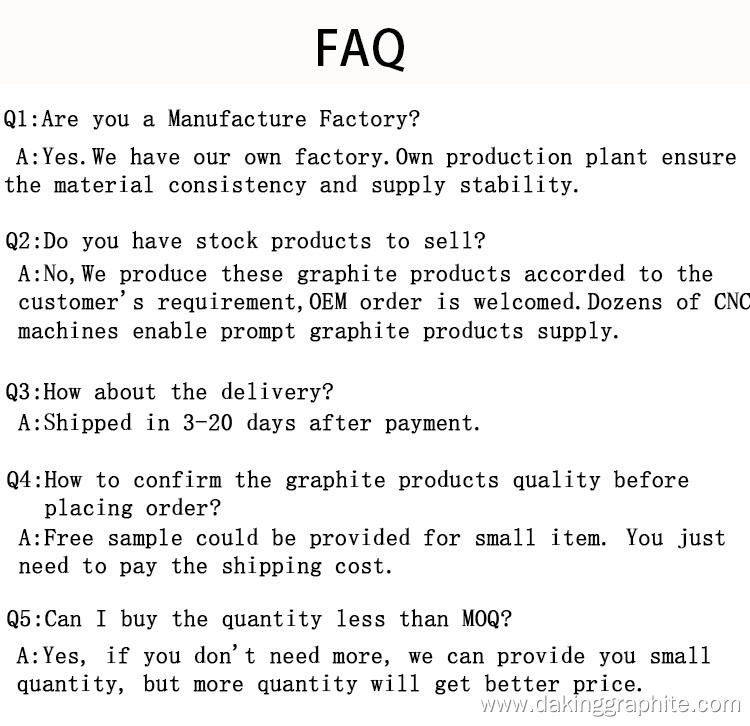

PACKAGE:

Veneer cases or wooden cases or according to customers’ requirement.

DELIVERY TIME:

3-20 days after confirming order,detail delivery date should be decided according to

production season and order quantity.

Get in touch

If you have any questions about our products or services, feel free to reach out to customer service team. Provide unique experiences for everyone involved with a brand. We've got preferential price and best-quality products for you.

RECOMMENDED

They are all manufactured according to the strictest international standards. Our products have received favor from both domestic and foreign markets.

They are now widely exporting to 200 countries.